Skinny Propellers versus Beefy Propellers. It’s one of our favorite debates, and, yes, we’ve written about it extensively here and here, but as a quick recap our view of the world is this:

- Skinny propellers are the result of an unhappy trade-off resulting in inefficient sadness. The propeller is going too fast and the electric motor is going too slow.

- Beefy propellers are like steak. The thicker the better. Plus everyone is happy when they are eating steak. And because Modovolo’s proprietary hub design enables the electric motor to spin at high efficiency and enables the Modovolo Lift’s a beefy propeller to spin at low speed, the Lift produces a lot more thrust much more efficiently than anything on the market.

We thought that this debate started when we came out of stealth-mode and publicly launched Modovolo in March 2024. But it turns out that this debate goes back to the very beginning of heavier-than-air flight.

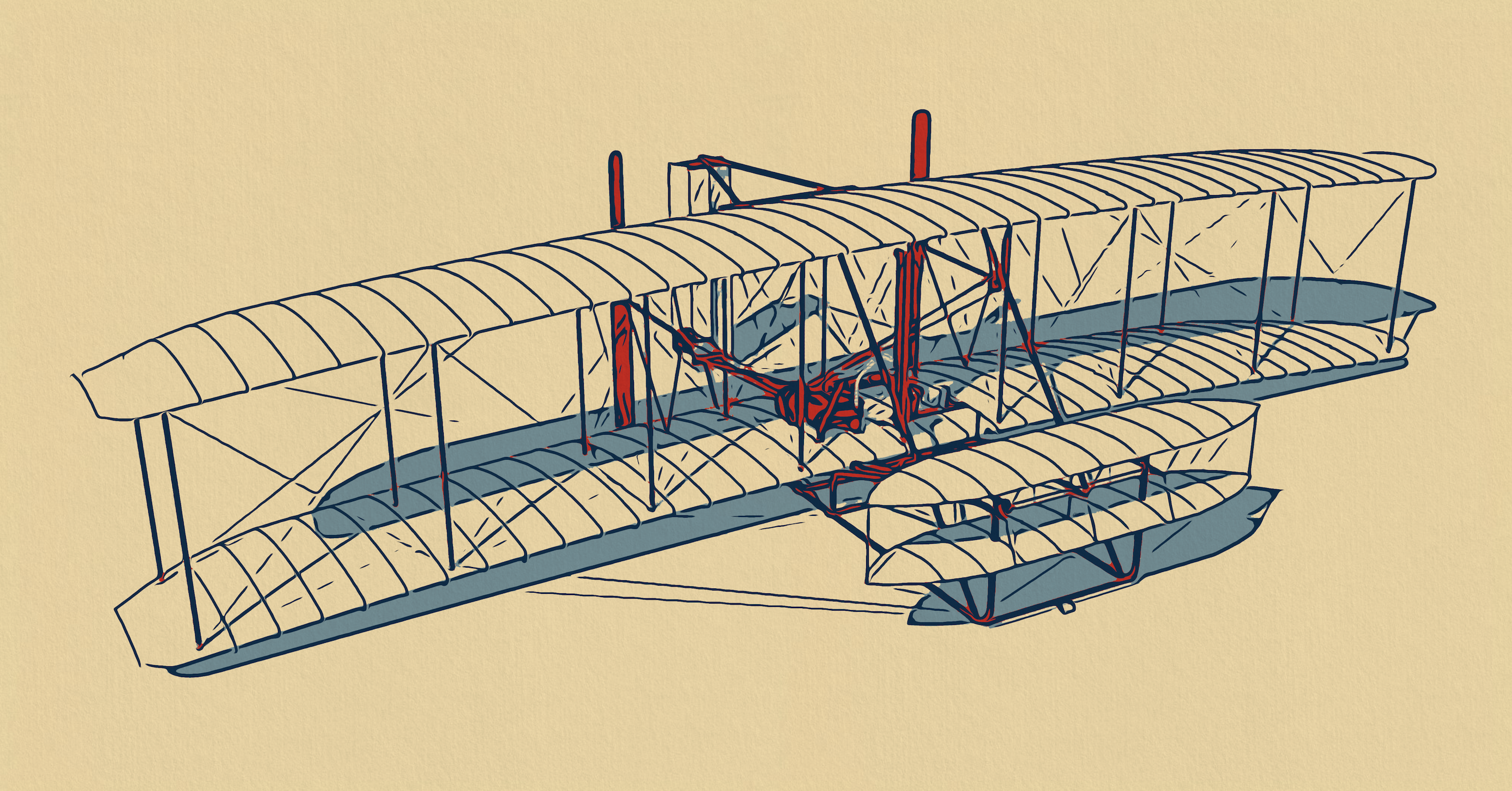

Yes, the Wright Brothers were beefy-propeller freaks too.

In a 2002 paper (we’re not exactly at the cutting edge of historical research, but you knew that already) entitled “Propeller Performance Tests of Wright Brothers’ Bent-End Propellers,” the authors describe the evolution of the Wrights’ thinking on propeller design and the simply epic amount of efficiency they were able to achieve by going to Beefy Propellers. And the Wrights did this all by experiment and hand carving the blades – which is just insane.

Just like every contemporary, the Wrights started with skinny propellers, but it was soon apparent that these performed poorly. These propeleers flexed at even low RPMs (like 400 to 500) which changed the pitch of the blade – and radically decreased the already poor efficiency.

That’s when the Wright Brothers went beefy. They widen the blades substantially decreased the flexing but not enough – they added triangles to the ends to further widen the trailing edges. This worked beautifully and when the Wrights did their public demonstrations, observers noted that the ends were “bent” – and the name “bent-end propeller” stuck.

How good were these beefy “bent-end” propellers? Well, most modern propellers convert about 83% of their rotational energy to thrust. And the beefy “bent-end” propellers were 78%. Not bad for hand-carving in a bike shop.

And what about Modovolo’s genetic-algorithm-designed beefy propellers? Well, we’re north of 93%. Not bad for a garage start-up based in Upstate NY.