I have to confess. Elon Musk is one of my heroes so I shamelessly copy a lot of his thinking. One of my favorite things that he does is use FPT (i.e., First Principles Thinking) to analyze and explain problems. Using FPT, Elon asks and thinks about the essence of the problem to its essential components – and only then he does he start to think about the solution.

Like when he was first contemplating the possibility of mass producing the electric car, everyone told him that it would never happen because the cost of the battery would always be too expensive. But then using FPT he asked: how much do the materials in a battery cost? Turns out, not much. The lithium, aluminum, and other stuff are a small fraction of the total cost of a battery, so the real cost was lazy engineering and inefficient manufacturing.

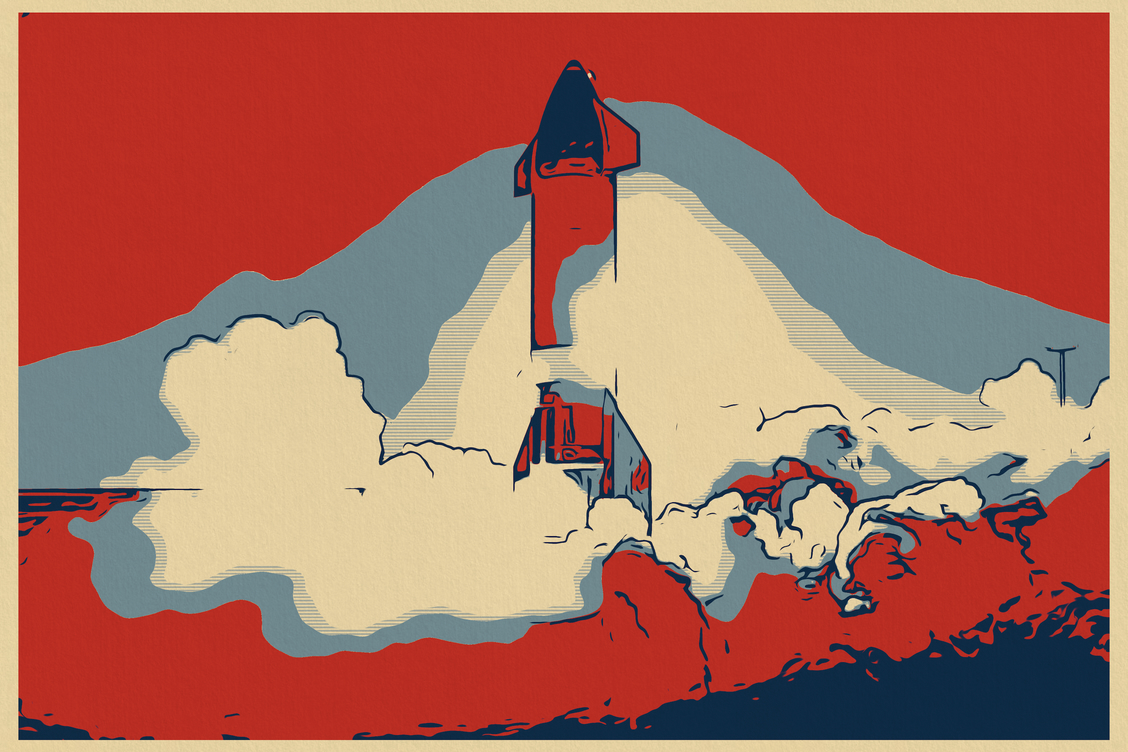

He had the same experience with rockets. The current process of designing and building rockets meant that it cost $10,000 per pound to put something into orbit. Yet, just like the battery for cars, the actual cost of the materials to build a rocket is quite low and that means all the cost in a standard rocket is from the same lazy engineering and inefficient manufacturing.

It’s something that Elon now calls the “Idiot Factor.” The engineers working on those batteries and rockets did not think through the true problem and true cost drivers and instead settled on the obvious solution, even though it was expensive in money or time or both. So in other way of putting it, the “Idiot Factor” really means failing to use FPT.

What’s an example of the Idiot Factor? Well, like any rocket engineers, Elon and his team contemplated using carbon fiber, Kevlar, and other exotic materials to reduce weight – a good thing. But if you just focus on reducing weight in isolation, it leads to odd outcomes. Kevlar, while light and strong, is very difficult to work with and requires a lot of very expensive equipment and can’t be scaled easily. Plus when you added heat shielding and other parts, it was really no lighter than using stainless steel.

So why use Kevlar? Stainless steel is super cheap – not only to buy itself but the manufacturing equipment to bend, weld, and attach is likewise cheap to buy and use. The result has been a dramatic drop in cost to put something in orbit that will soon be in the hundreds of $ per pound.

How does this apply to drones?

Well, we at Modovolo like to modestly think that we are the only ones in the drone industry using FPT and, therefore, everyone else is experiencing the Idiot Factor.

In our next article, we’ll dive into the reasons for Modovolo’s hubris and the all important Cost-Per(Flight)-Minute metric.